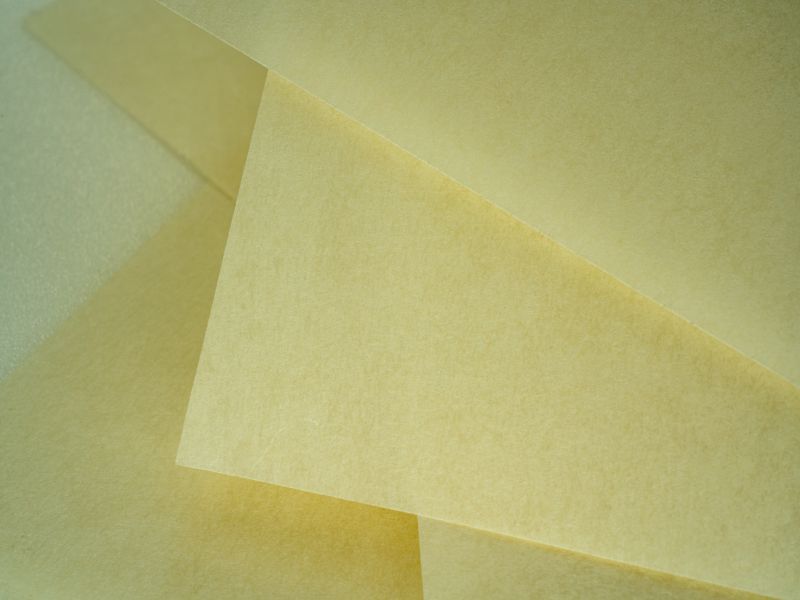

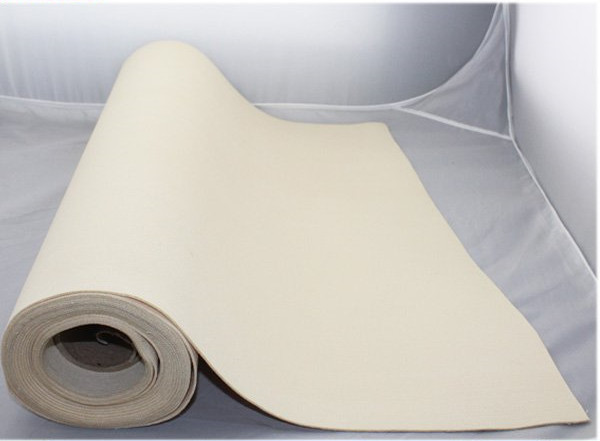

Heat Resistance PPS Fiber Veil For Circuit Board

Heat-resistant PPS fiber veil for circuit boards has excellent fluidity and low shrinkage and is suitable for precision molding of connectors and socket circuit boards.

Heat-resistant PPS fiber veil for circuit boards offers excellent stiffness and mechanical integrity for reliable assembly and is one of the most stable material choices for all SMT soldering methods.

1. Product Introduction

The heat-resistant PPS fiber veil for circuit boards is a high-performance polymer mainly used for manufacturing heat-resistant, chemical corrosion-resistant, and wear-resistant materials. The heat-resistant PPS fiber veil for circuit boards has a wide range of applications, such as in industries such as automobiles, electronics, aerospace, and industrial manufacturing.

Due to its excellent high-temperature resistance, chemical corrosion resistance, high strength, and stiffness, the heat-resistant PPS fiber veil for circuit boards has become an indispensable material in the electronics industry.

In the electronics industry, a heat-resistant PPS fiber veil for circuit boards is also a very important material. It is used to manufacture packaging materials, high-temperature wiring boards, and other electronic components for various integrated circuits (ICs). Compared with other plastics, the decomposition temperature of the heat-resistant PPS fiber veil used in circuit boards is higher, so it can withstand higher working temperatures and current densities than other materials.

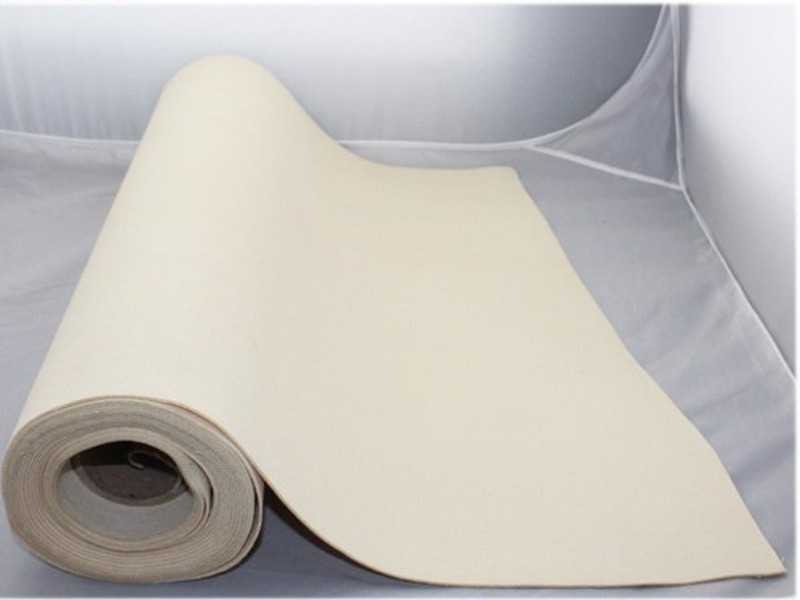

2. Product Feature

High-temperature resistance: The heat-resistant PPS fiber veil for circuit boards has excellent high-temperature stability and can be used for a long time at high temperatures up to 260°C without decomposition or degradation. At the same time, the heat-resistant PPS fiber veil for circuit boards can also withstand higher surface temperatures. In a high-temperature environment, whether it is room temperature or low temperature, the heat-resistant PPS fiber veil for circuit boards still maintains good rigidity and strength

Wear resistance: The heat-resistant PPS fiber veil for circuit boards has excellent wear resistance and can withstand high-speed movement and heavy-load friction for a long time without deformation, cracks, and wear. This feature makes the heat-resistant PPS fiber veil for circuit boards have great application prospects in the manufacture of high-quality industrial machinery parts.

Chemical corrosion resistance: The heat-resistant PPS fiber veil for circuit boards has excellent chemical stability and can resist the influence of various acids, alkalis, salts, and other corrosive substances. The heat-resistant PPS fiber veil for circuit boards has very good Corrosion resistance.

Mechanical strength: The heat-resistant PPS fiber veil for circuit boards has high mechanical strength and rigidity, and can maintain uniform reduction under various climatic conditions and environments. Therefore, heat-resistant PPS fiber veil for circuit boards is widely used in the manufacture of high-quality industrial components and consumable parts.

Electrical insulation performance: The heat-resistant PPS fiber veil used for circuit boards has good electrical insulation characteristics. Its small dielectric constant, low-temperature coefficient, suitable volume, surface, and fractal distribution provide an important guarantee for the manufacture of electronic components.

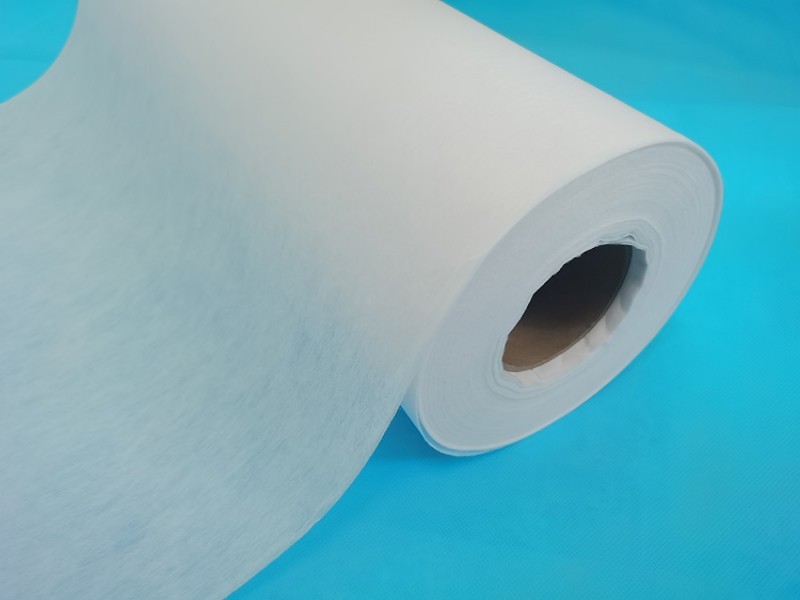

3. Product Details

Heat-resistant PPS fiber veil for circuit boards is a high-performance material, which is widely used in the manufacture of accessories in the electronics industry due to its excellent mechanical properties, chemical stability, and heat resistance.

The circuit board is veiled with heat-resistant PPS fiber to protect the integrated circuit chip and the connecting wires in it and prevent failures caused by factors such as temperature, corrosion, and mechanical damage. It has excellent high-temperature resistance, can withstand higher temperatures without failure, and helps to maintain the function and performance of advanced integrated circuits.

Because of its high strength, rigidity, and temperature resistance, heat-resistant PPS fiber veils for circuit boards are widely used in the manufacture of high-temperature industrial equipment. PPS has good electrical insulation properties, allowing it to maintain the same level when operating in high-temperature environments with safety and reliability.

The heat-resistant PPS fiber veil for the circuit board is a superior engineering material with high-temperature resistance, corrosion resistance, and mechanical integrity, and the substance formed after melting blocks ultraviolet rays. Therefore, the heat-resistant PPS fiber veil for circuit boards is widely used in the manufacture of electrical equipment, communication equipment, packaging materials, circuit chips, and other electronic accessories.