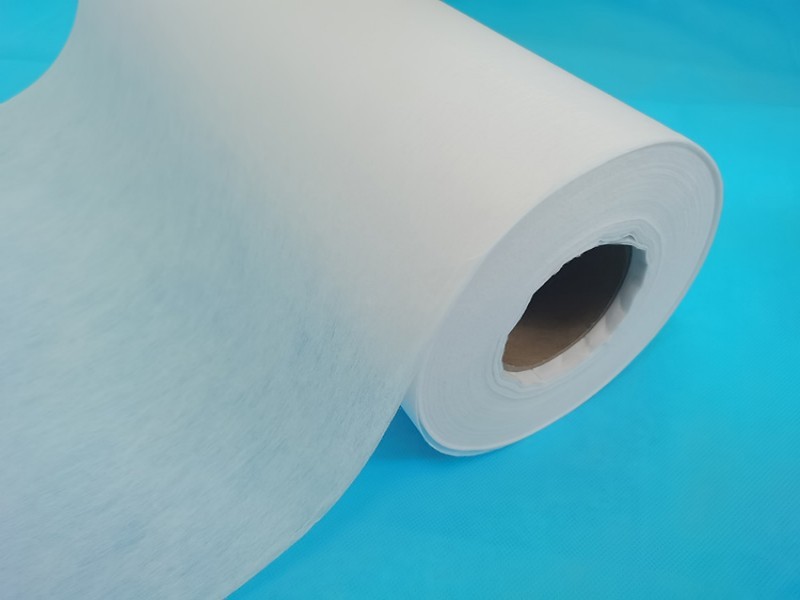

Heat Resistance PPS Fiber Veil For Thermistor

The heat-resistant PPS fiber veil used for thermistors can be used for a long time under high-temperature conditions and can withstand mechanical environments such as vibration, impact, centrifugation, and insertion and extraction during use.

The heat-resistant PPS fiber veil used for thermistors also has flame retardancy and chemical corrosion resistance.

1. Product Introduction

Electric skateboards are based on traditional human-powered skateboards and are powered by electric kits. Electric skateboards are generally divided into two-wheel drive or single-wheel drive. The most common transmission methods are: hub motor (HUB) and belt drive. The main source of power is lithium battery pack.The control method of the electric scooter is the same as that of the traditional electric bicycle, which is easy to be learned by the driver. It is equipped with a detachable and foldable seat. Electric skateboards are based on traditional human-powered skateboards and are powered by electric kits. Electric skateboards are generally divided into two-wheel drive or single-wheel drive. The most common transmission methods are: hub motor (HUB) and belt drive.

The heat-resistant PPS fiber veil used for thermistors has excellent heat resistance, corrosion resistance, flame retardancy, rigidity, and electrical properties, as well as a good self-lubricating effect and certain load-bearing capacity.

Its biggest advantage is that it can be combined with different fillers or matrices to meet specific usage requirements through special treatment methods under certain processing conditions. The heat-resistant PPS fiber veil for thermistors is a new variety with good development potential and competitiveness.

The heat-resistant PPS fiber veil used for thermistors can be applied to fields with high requirements for material conductivity, such as electrical engineering, electromagnetic shielding, electronic information, etc. The heat-resistant PPS fiber veil used for thermistors enables conductive materials to have excellent comprehensive performance.

2. Product Feature

Heat resistance for continuous use at 200°C or higher

High resistance to chemicals, heat, vibration, and shock

Excellent strength, plasticity, and rigidity over a wide temperature range

Excellent dimensional stability under most environmental conditions

Advanced electrical performance at high temperatures, high humidity, and high frequency

3. Product Details

Electric skateboards are based on traditional human-powered skateboards and are powered by electric kits. Electric skateboards are generally divided into two-wheel drive or single-wheel drive. The most common transmission methods are: hub motor (HUB) and belt drive. The main source of power is lithium battery pack.The control method of the electric scooter is the same as that of the traditional electric bicycle, which is easy to be learned by the driver. It is equipped with a detachable and foldable seat. Electric skateboards are based on traditional human-powered skateboards and are powered by electric kits. Electric skateboards are generally divided into two-wheel drive or single-wheel drive. The most common transmission methods are: hub motor (HUB) and belt drive.

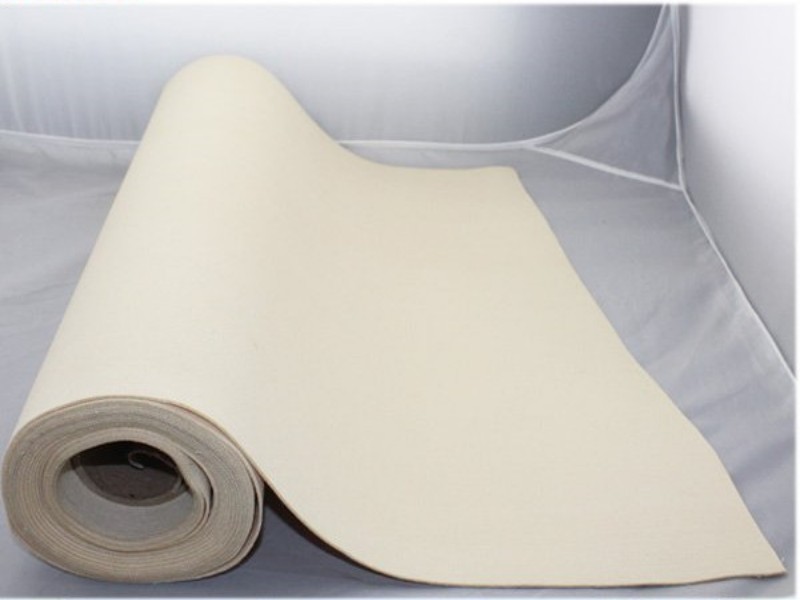

Heat-resistant PPS fiber veils for thermistors have good electrical properties, mechanical properties, and heat resistance properties under high-temperature conditions.

The heat-resistant PPS fiber veil for thermistors is also a material that is inherently flame-retardant without adding flame retardants. At the same time, the heat-resistant PPS fiber veil for thermistors is insoluble in any known solvent below 200 ° C. It is suitable for organic, Inorganic acid and alkali resistance is very high, it is second only to polytetrafluoroethylene anti-chemical corrosion material.

The heat-resistant PPS fiber veil for thermistors is the only one that can provide sufficient dimensional stability among all the thermoplastic engineering plastics used, and it is the material that can ensure contact pressure for long-term use. In summary, PPS composite material is an insulating material that fully meets the requirements of high-performance electrical connectors.

4. Transportation

Recommended to place it vertically.

Avoid moisture, squeezing, and stacking heavy objects during transportation.

Appropriately reducing the width of the rolls at the container entrance for packing needs.

5. Storage & Use

Storage: Store in a dry, ventilated place to avoid moisture.

Sufficient storage space should be reserved to avoid squeezing and stacking.

Recommended period of use: within 6 months.