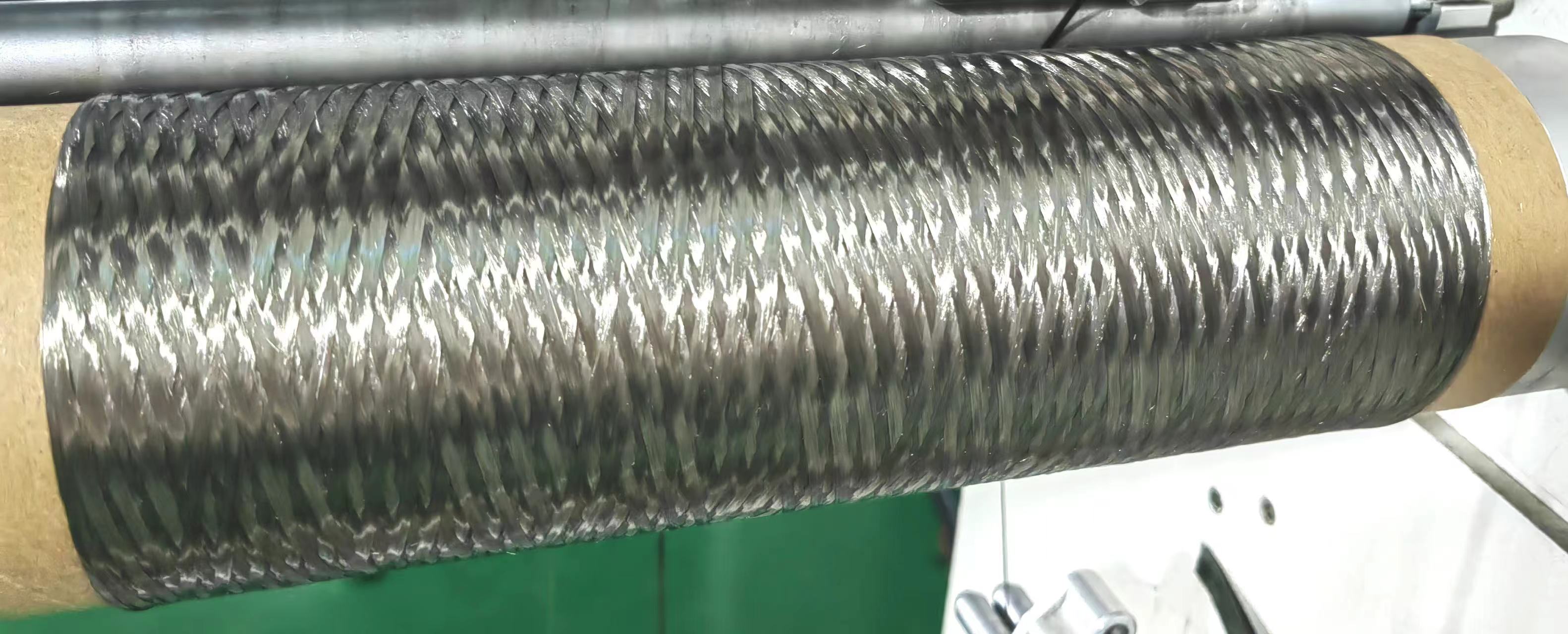

Nickle Plated Conductive Carbon Fiber

Nickle Plated Conductive Carbon Fiber is an advanced material that combines the superior properties of carbon fiber with a nickle-plated coating, resulting in enhanced conductivity and durability. This product is designed for applications requiring high-performance materials with both electrical conductivity and mechanical strength. The nickle-plating process significantly improves the fiber's resistance to corrosion while maintaining its lightweight nature, making it ideal for various industries.

Nickle Plated Conductive Carbon Fiber

1. Product Introduction

Nickle Plated Conductive Carbon Fiber is an advanced material that combines the superior properties of carbon fiber with a nickle-plated coating, resulting in enhanced conductivity and durability. This product is designed for applications requiring high-performance materials with both electrical conductivity and mechanical strength. The nickle-plating process significantly improves the fiber’s resistance to corrosion while maintaining its lightweight nature, making it ideal for various industries.

The incorporation of a Nickle Plated layer provides enhanced protection against environmental factors, ensuring a long lifespan even in challenging conditions. With the added benefit of conductivity, Nickle Plated Conductive Carbon Fiber is a versatile and innovative solution for modern technological requirements.

2. Product Applications

Nickle Plated Conductive Carbon Fiber is widely used across multiple industries due to its unique combination of properties. Some common applications include:

1. Electromagnetic Shielding: The conductive nature of the fiber makes it highly suitable for applications requiring electromagnetic interference (EMI) shielding in electronics and communication devices.

2. Aerospace Components: Due to its lightweight yet strong structure, Nickle Plated Conductive Carbon Fiber is often employed in the aerospace sector, providing both durability and conductivity.

3. Automotive Industry: This material is used in electric vehicles and hybrid cars for components that require both strength and conductivity.

4. Medical Devices: Its biocompatibility and conductivity make it ideal for medical equipment, especially those related to diagnostics and patient monitoring.

5. Energy Storage: The fiber is employed in battery technology, improving the efficiency and performance of energy storage systems through its conductive properties.

3. Product Features

The Nickle Plated Conductive Carbon Fiber offers several distinctive features that make it stand out in various applications:

1. Nickle Plated Surface: The nickle-plated layer significantly enhances the fiber's electrical conductivity, making it suitable for a wide range of electronic and industrial uses. The plating also provides an additional protective layer that improves resistance to corrosion and wear.

2. Lightweight with High Strength: Despite the conductive coating, the material retains the lightweight yet robust properties of carbon fiber, making it a perfect fit for applications where both strength and minimal weight are crucial.

3. Corrosion Resistance: The Nickle Plated coating offers superior resistance to oxidation and corrosion, extending the product's lifespan in harsh environmental conditions.

4. Thermal and Electrical Conductivity: This material excels in applications requiring both heat dissipation and electrical conductivity, providing a reliable solution for complex industrial challenges.

5. Versatility: The combination of nickle plating and carbon fiber makes this product suitable for industries ranging from aerospace to medical, offering flexibility across sectors requiring high-performance materials.

Item | Test standard | Unit | Classic value | |

Mechanical Properties | Tensile strength | ISO11566 | MPa | 3000 |

Tensile modulus | ISO11566 | GPa | 160 | |

Enlongation at break | ISO11566 | % | 1.3 | |

| ||||

Electrical property | Resistivity | QJ3074 | Ω.cm | 8.23*10-5 |

| ||||

Others | Bulk density | ISO10119 | g/cm3 | 3.2 |

Linear density | ISO11566 | g/km | 1630 | |

Tow | ISO11566 | ends | 12000 | |

Filament diameter |

| μm | 7.3 | |

Coating thickness |

| μm | 0.3 | |

Nickel content |

| % | 50 | |

Cross-sectional area |

| mm2/tow | 0.55 | |

Twist |

|

| none | |