Nonwoven Silicon Fabric for Millimeter-Wave Radar

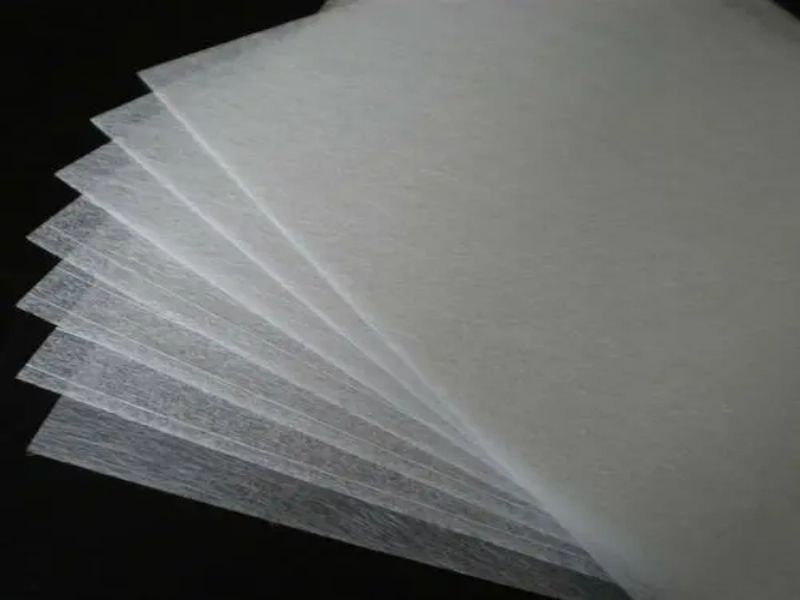

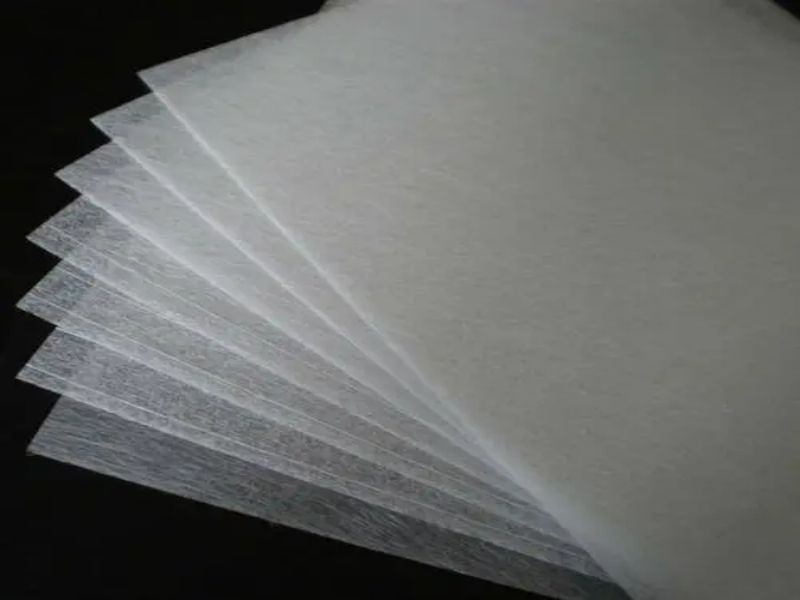

Nonwoven Silicon Fabric for Millimeter-Wave Radar is a high-performance material designed for use in radar systems. Its unique structure ensures minimal signal loss while providing durability and flexibility. Ideal for millimeter-wave radar applications, it acts as a transparent medium for radar waves, allowing for reliable signal transmission. This fabric is commonly used in radar covers, antennas, and sensor enclosures, where maintaining signal clarity and reducing interference are crucial. With high resistance to environmental factors like temperature and moisture, Nonwoven Silicon Fabric is a trusted solution for both aerospace and automotive industries. It delivers outstanding performance in demanding radar applications.

Specification | Quartz Fiber Nonwoven | Quartz Fiber Veil |

Thickness | 0.1 - 0.5 mm | 0.05 - 0.2 mm |

Weight | 100 - 200 g/m² | 50 - 150 g/m² |

Temperature Resistance | Up to 1050°C | Up to 1050°C |

Chemical Resistance | Excellent | Excellent |

Tensile Strength | High | High |

Applications | Aerospace, Automotive, Chemical Processing | Aerospace, Automotive, Chemical Processing |

Environmental Impact | Low | Low |

1. Product Overview

Nonwoven Silicon Fabric for Millimeter-Wave Radar is a specialized material designed to meet the advanced requirements of millimeter-wave radar applications. This fabric combines the strength and flexibility of nonwoven technology with the unique properties of silicon to create an efficient radar-transparent medium. The nonwoven structure ensures lightweight and durable performance, while the silicon composition optimizes the transmission of millimeter-wave signals. This makes it an essential material in various radar systems, particularly those used for high-frequency and long-range sensing. It is engineered to withstand harsh environmental conditions while maintaining excellent performance in radar transparency.

2. Applications

Nonwoven Silicon Fabric for Millimeter-Wave Radar is primarily used in radar systems for various purposes, including but not limited to:

· Radar Transparent Covers: Protects radar equipment without interfering with millimeter-wave signal transmission.

· Antenna Covers and Radomes: Ideal for applications requiring precision, such as aviation, automotive, and defense sectors.

· Microwave Signal Transmission: Suitable for environments where microwave signals need to be transmitted with minimal loss.

· Sensor Enclosures: Protects sensitive radar sensors while allowing uninterrupted signal propagation.

· Weather and Environmental Monitoring Systems: Assists in providing radar protection in weather radar equipment, ensuring clear data reception and transmission.

3. Features

The Nonwoven Silicon Fabric for Millimeter-Wave Radar boasts several key characteristics that enhance its suitability for high-performance radar applications:

· High Transparency to Millimeter-Waves: Designed to minimize signal attenuation, ensuring maximum radar performance.

· Durable and Lightweight: Nonwoven fabric construction offers durability while keeping weight low, making it ideal for aerospace and automotive applications.

· High-Temperature Resistance: Resistant to extreme temperatures, enabling reliable performance in diverse operational environments.

· Flexible and Formable: The fabric's flexibility allows it to be molded into various shapes and sizes, adapting easily to different radar equipment designs.

· Environmentally Resistant: Provides protection against harsh weather conditions, including UV rays and moisture, without compromising radar function.

· Cost-Effective: Offers an efficient balance between performance and cost, making it a practical choice for manufacturers and end-users.

· Non-toxic and Safe: The silicon material is non-toxic, ensuring safety in all applications, particularly those in sensitive environments like hospitals or aircraft.

By incorporating Nonwoven Silicon Fabric for Millimeter-Wave Radar into radar systems, manufacturers and engineers can improve signal quality, reduce maintenance costs, and ensure consistent performance in critical operations.