Carbon Fiber Punched Felt: The Ultimate Solution for High-Performance Filtration and Insulation

2025-02-18 17:36

In the world of advanced materials, carbon fiber punched felt stands out as a versatile and high-performance solution for a wide range of industrial applications. At Saxobran, we specialize in providing top-quality carbon fiber punched felt that meets the demanding needs of industries such as aerospace, automotive, energy, and more. In this article, we will explore the unique properties of carbon fiber punched felt, its applications, and why it is the material of choice for high-performance filtration and insulation.

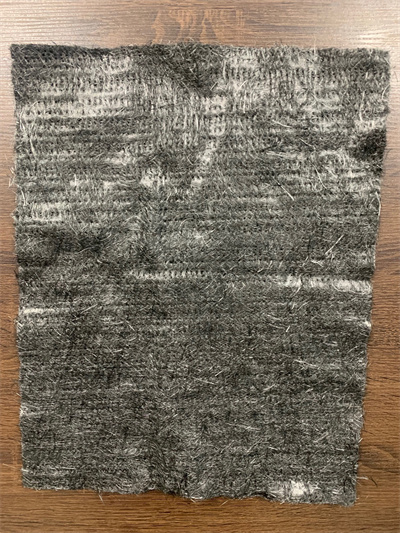

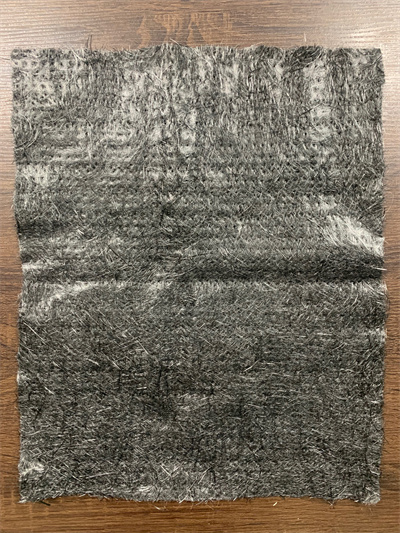

What is Carbon Fiber Punched Felt?

Carbon fiber punched felt is a non-woven fabric made from carbon fibers that are needled together to form a dense, uniform mat. This material is known for its exceptional strength, lightweight properties, and resistance to high temperatures and corrosive environments. The punching process enhances the felt's structural integrity, making it ideal for applications that require durability and reliability.

Key Properties of Carbon Fiber Punched Felt

1. High Temperature Resistance: Carbon fiber punched felt can withstand extreme temperatures, making it suitable for use in environments where other materials would fail.

2. Excellent Filtration Efficiency: The dense structure of the felt allows for high filtration efficiency, capturing even the smallest particles.

3. Lightweight and Strong: Despite its lightweight nature, carbon fiber punched felt offers remarkable strength and durability.

4. Chemical Resistance: This material is resistant to a wide range of chemicals, ensuring long-lasting performance in harsh conditions.

5. Thermal Insulation: Carbon fiber punched felt provides excellent thermal insulation, making it ideal for applications that require heat management.

Applications of Carbon Fiber Punched Felt

Carbon fiber punched felt is used in a variety of industries due to its unique properties. Some of the most common applications include:

1. Filtration Systems: The material's high filtration efficiency makes it ideal for use in air and liquid filtration systems, including those used in the automotive and aerospace industries.

2. Thermal Insulation: Carbon fiber punched felt is widely used in thermal insulation applications, such as in furnaces, ovens, and other high-temperature environments.

3. Sound Absorption: The material's dense structure also makes it effective for sound absorption, reducing noise levels in industrial settings.

4. Sealing and Gasketing: Carbon fiber punched felt is used in sealing and gasketing applications where high temperature and chemical resistance are required.

5. Composite Reinforcement: The material can be used as a reinforcement in composite materials, enhancing their strength and durability.

Why Choose Saxobran for Carbon Fiber Punched Felt?

At Saxobran, we are committed to providing our clients with the highest quality carbon fiber punched felt available. Our products are manufactured using state-of-the-art technology and undergo rigorous quality control processes to ensure they meet the highest industry standards. Whether you need carbon fiber punched felt for filtration, insulation, or any other application, we have the expertise and resources to meet your needs.

Conclusion

Carbon fiber punched felt is a remarkable material that offers a unique combination of strength, durability, and resistance to extreme conditions. Its versatility makes it an essential component in a wide range of industrial applications. If you are looking for a reliable supplier of high-quality carbon fiber punched felt, look no further than Saxobran. Contact us today to learn more about our products and how we can help you achieve your project goals.

By choosing carbon fiber punched felt from Saxobran, you are investing in a material that delivers exceptional performance and reliability. Let us help you take your projects to the next level with our advanced carbon fiber solutions.