- Home

- >

- Products

- >

- Carbon Fiber Veil

- >

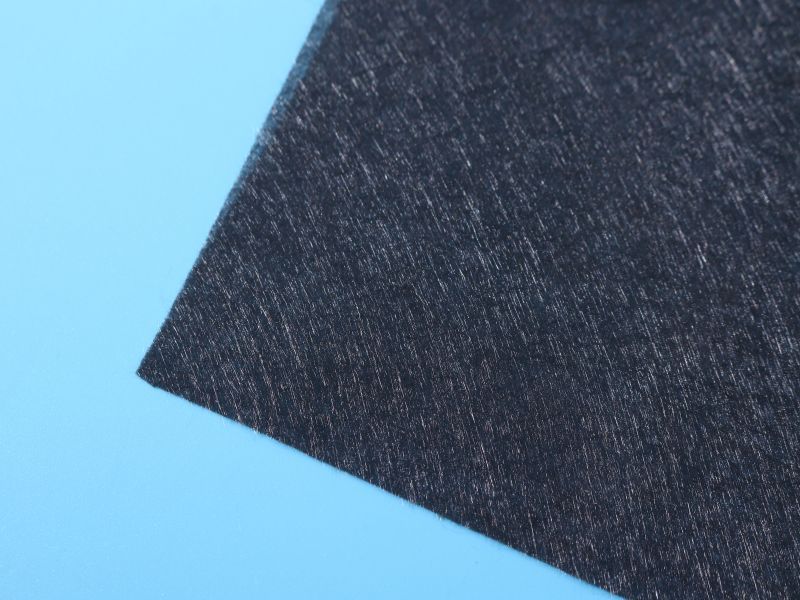

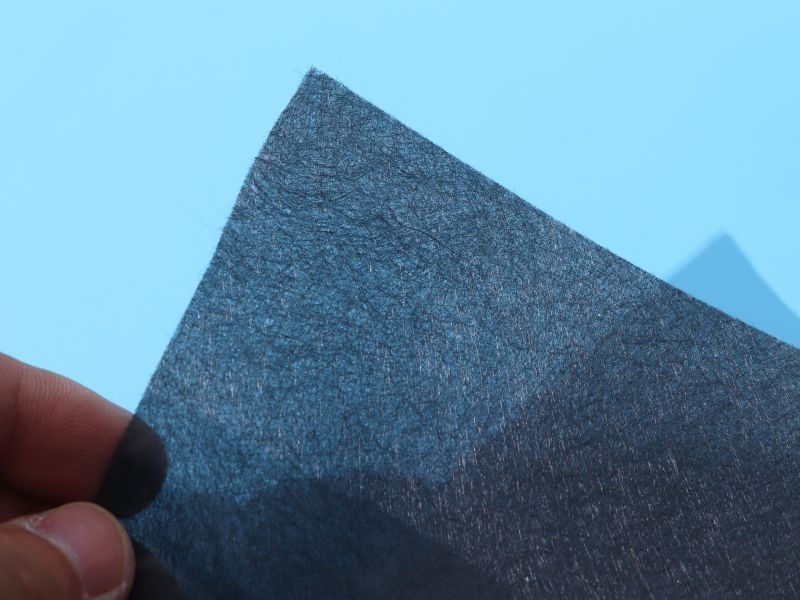

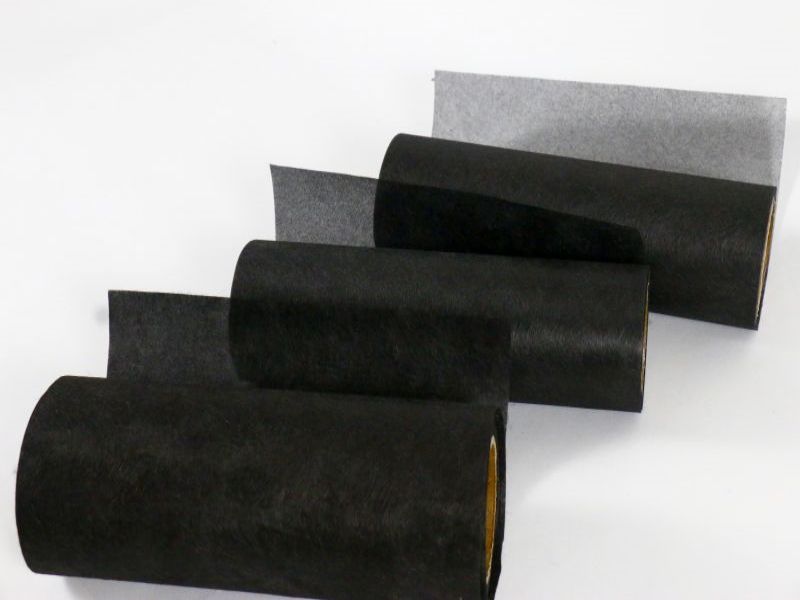

Carbon Fiber Veil

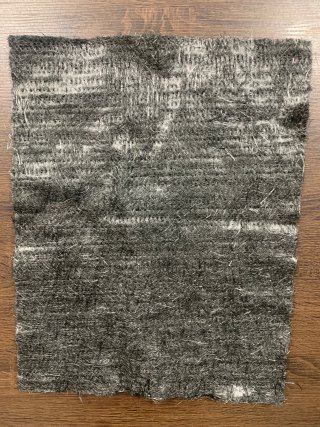

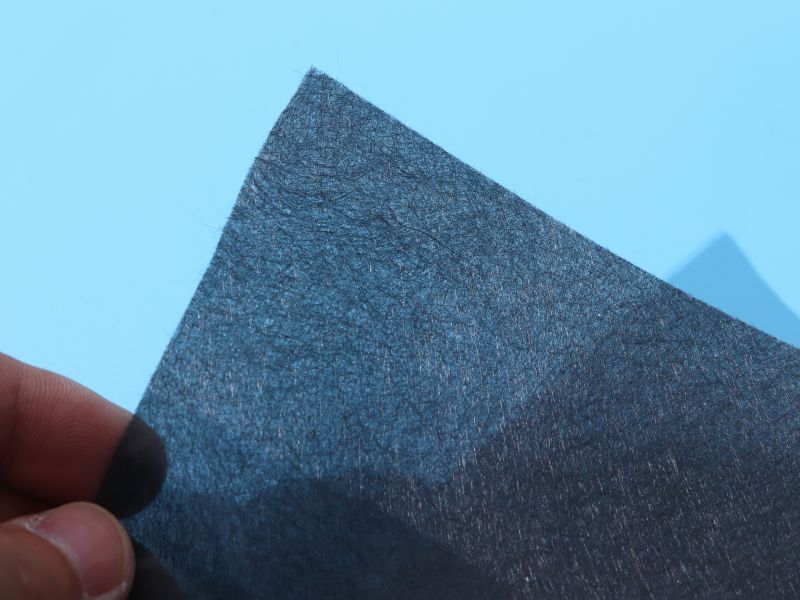

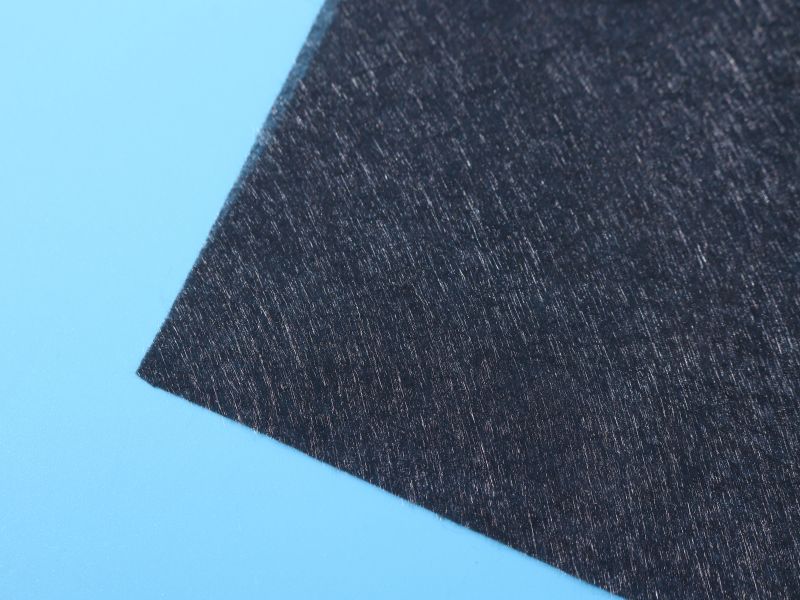

Carbon Fiber Veil is an advanced composite material known for its exceptional lightweight properties and superior strength. This innovative product is made from finely woven carbon fibers, offering outstanding flexibility and durability. It is ideal for a wide range of applications, including automotive, aerospace, and sports equipment. The veil enhances structural integrity while minimizing weight, making it perfect for projects where performance is crucial. Its resistance to corrosion and environmental degradation ensures longevity, making it a preferred choice for manufacturers seeking reliable and efficient materials. Carbon Fiber Veil is customizable, allowing it to meet diverse industry needs effectively.

Product Overview

The Carbon Fiber Veil is a lightweight and durable material made from high-quality carbon fiber strands. Known for its exceptional strength and versatility, this product is ideal for various applications. The Carbon Fiber Veil is designed to enhance structural integrity while remaining flexible, making it suitable for both industrial and consumer use.

Product Applications

· Automotive Industry: Used for reinforcing body panels and components.

· Aerospace: Provides lightweight strength in aircraft design.

· Sports Equipment: Enhances performance and durability in gear.

· Marine Applications: Protects against corrosion in boat manufacturing.

· Construction: Improves strength in concrete and composite structures.

Product Features

· Lightweight: Reduces overall weight without compromising strength.

· High Strength-to-Weight Ratio: Offers remarkable strength while maintaining flexibility.

· Corrosion Resistance: Withstands harsh environmental conditions.

· Easy to Work With: Compatible with various resin systems for seamless integration.

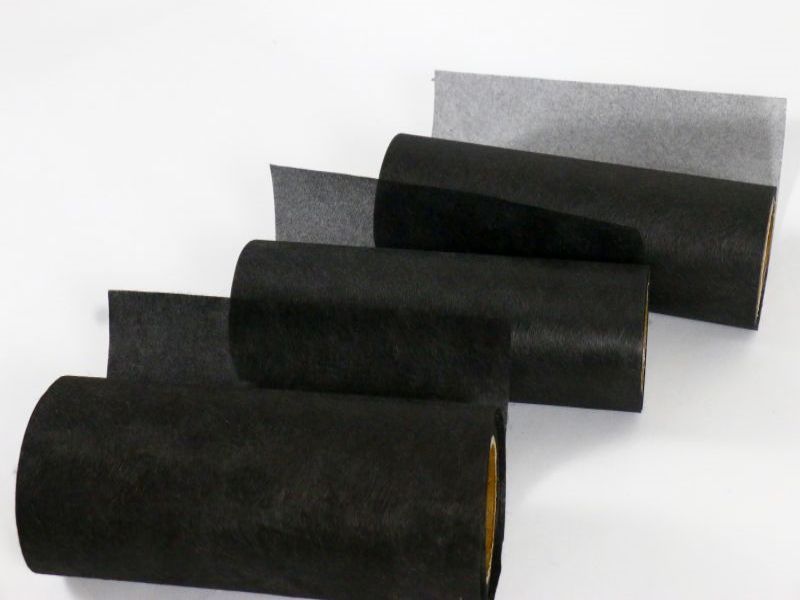

· Customizable: Available in different thicknesses and widths to meet specific needs.

The Carbon Fiber Veil stands out as a premier choice for those seeking quality and performance across multiple industries.

| Item Code | Area Weight | Surface Resistance | Binder Content | Moisture Content | Tensile Strength | Thickness |

| BN-005 | 5g/m2 | - | 10%±2% | ≤0.3% | - | 0.05±0.01mm |

| BN-006 | 6g/m2 | - | 10%±2% | ≤0.3% | ≥5N/50mm | 0.06±0.01mm |

| BN-008 | 8g/m2 | - | 10%±2% | ≤0.3% | ≥7N/50mm | 0.08±0.01mm |

| BN-010 | 10g/m2 | ≤15Ω | 10%±2% | ≤0.3% | ≥11N/50mm | 0.09±0.01mm |

| BN-015 | 15g/m2 | ≤8Ω | 10%±2% | ≤0.3% | ≥16N/50mm | 0.15±0.02mm |

| BN-020 | 30g/m2 | ≤6Ω | 10%±2% | ≤0.3% | ≥21N/50mm | 0.20±0.03mm |

| BN-030 | 50g/m2 | ≤4Ω | 10%±2% | ≤0.3% | ≥31N/50mm | 0.30±0.03mm |

| BN-050 | 60g/m2 | ≤3Ω | 10%±2% | ≤0.3% | ≥40N/50mm | 0.50±0.04mm |