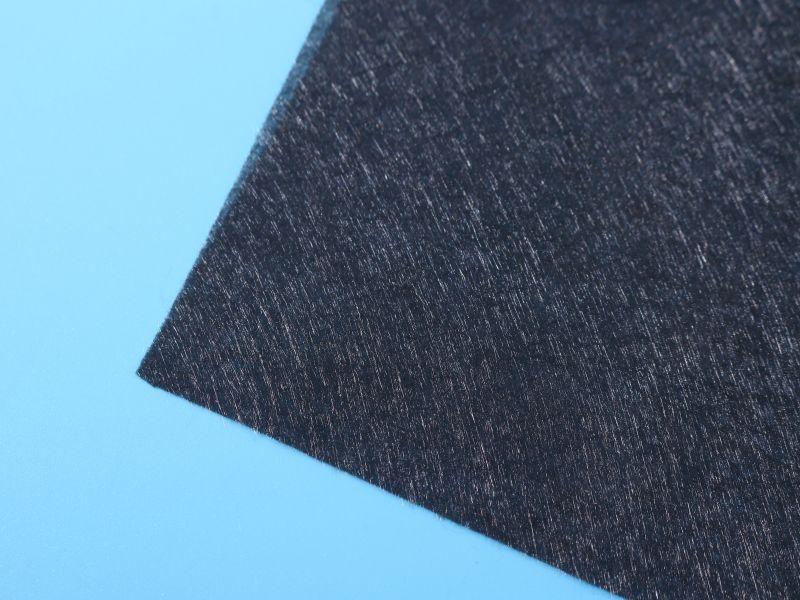

Carbon Paper Wet-laid Nonwoven Carbon Fiber Paper

Carbon Paper Wet-laid Nonwoven Carbon Fiber Paper is a highly durable and versatile material that combines the strength of carbon fibers with the flexibility of nonwoven textiles. Manufactured using a wet-laid process, this product exhibits exceptional performance in various applications. The carbon fiber composition enhances its conductivity, resistance to heat, and mechanical strength, making it ideal for industries where high-performance materials are required.

1. Product Overview

· Carbon Paper Wet-laid Nonwoven Carbon Fiber Paper is a highly durable and versatile material that combines the strength of carbon fibers with the flexibility of nonwoven textiles.

· Manufactured using a wet-laid process, this product exhibits exceptional performance in various applications.

· The carbon fiber composition enhances its conductivity, resistance to heat, and mechanical strength, making it ideal for industries where high-performance materials are required.

2. Applications

· Electronics: Used as conductive material in circuit boards, batteries, and capacitors due to its superior electrical conductivity.

· Automotive: Incorporated into brake pads, filters, and other high-performance parts for its ability to withstand high temperatures and mechanical stress.

· Aerospace: Ideal for components that need to endure extreme conditions, offering both lightweight and durable solutions for aircraft and spacecraft parts.

· Sports Equipment: Used in manufacturing parts of equipment like tennis rackets and bicycles, where strength-to-weight ratio is crucial.

· Energy: Applied in the production of fuel cells and other renewable energy technologies for its resistance to corrosion and electrical conductivity.

3. Product Features

· High Conductivity: The Carbon Fiber Paper’s conductive properties are crucial for its use in electronic and energy applications, providing enhanced performance.

· Lightweight and Strong: Despite being lightweight, the carbon fiber structure ensures remarkable mechanical strength, making the material suitable for demanding industries.

· High-Temperature Resistance: Can withstand extremely high temperatures, maintaining its integrity in challenging environments.

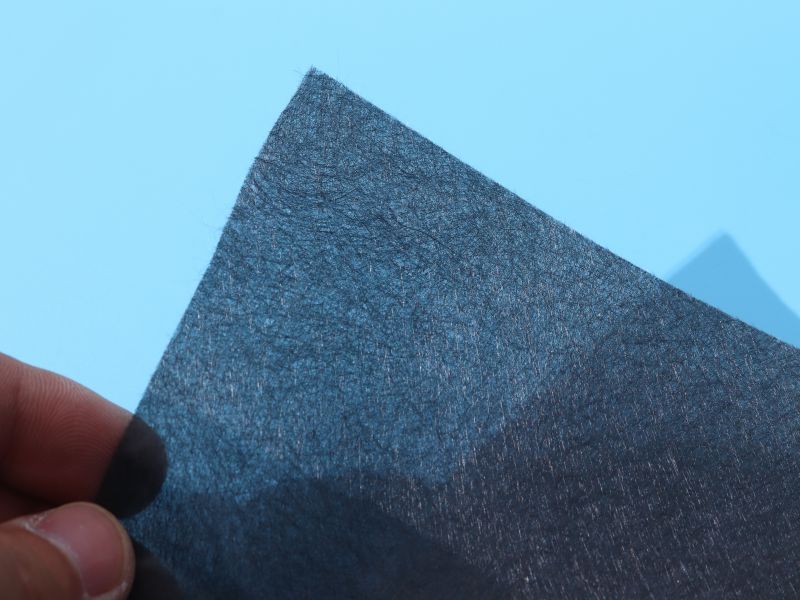

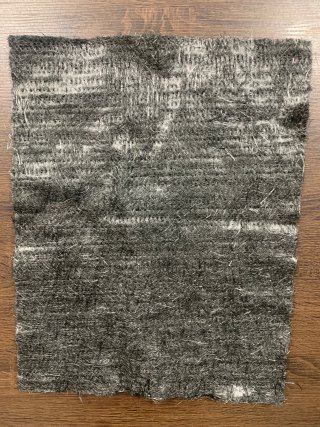

· Nonwoven Structure: The nonwoven nature of the paper provides excellent flexibility and durability, allowing it to maintain form and function even under stress.

· Wet-laid Manufacturing Process: The wet-laid process involves blending carbon fibers with a liquid medium, followed by filtering and drying. This method ensures uniform fiber distribution, resulting in a consistent material with superior properties. The process also allows for the creation of a flexible, nonwoven sheet that combines the performance benefits of carbon fibers with the versatile structure of nonwoven textiles. This method is critical for achieving the high performance and durability required in specialized applications.

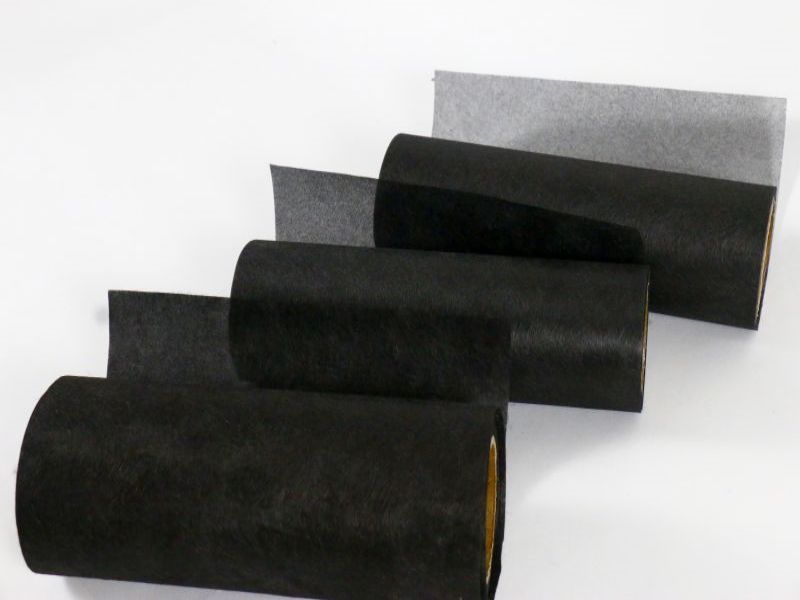

Area Weight | Thickness | Tensile Strength | Moisture Content |

g/m² | mm | N/50mm | % |

6±1 | 0.06±0.01 | 2.5±0.5 | ≤0.28 |

8±1 | 0.08±0.01 | 5.5±0.5 | ≤0.29 |

10±1 | 0.09±0.01 | 5.6±0.5 | ≤0.295 |

15±1 | 0.13±0.01 | 6.9±1 | ≤0.35 |

20±1 | 0.18±0.02 | 11±2 | ≤0.37 |

30±2 | 0.21±0.02 | 16.9±2 | ≤0.38 |

50±2 | 0.38±0.02 | 25.8±0.3 | ≤0.38 |