- Home

- >

- Products

- >

- Nomex Paper

- >

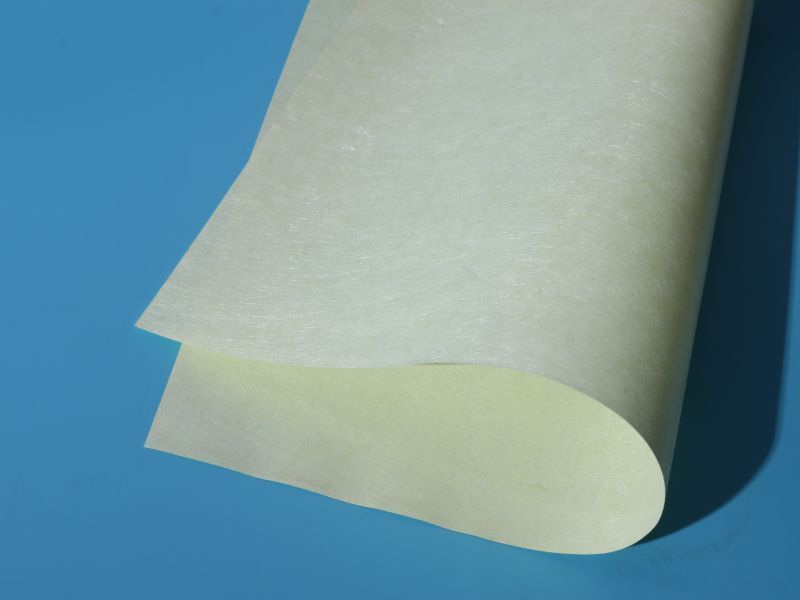

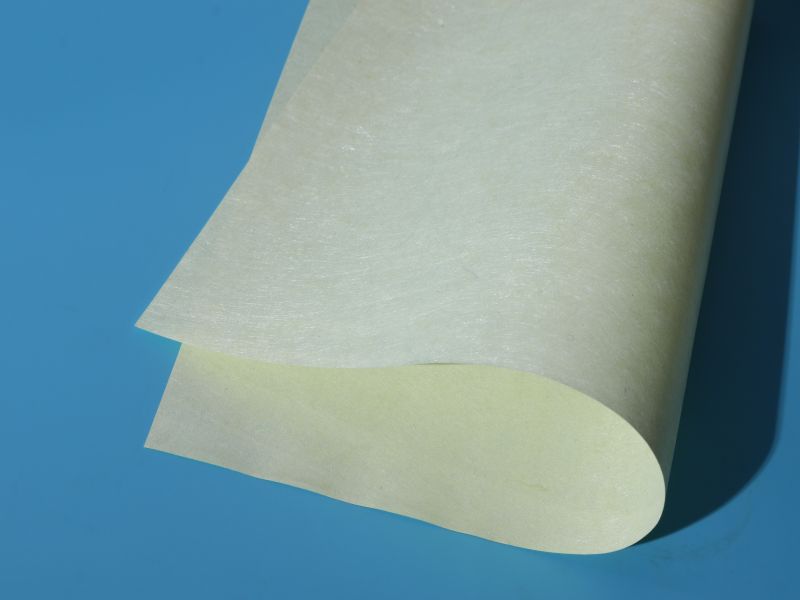

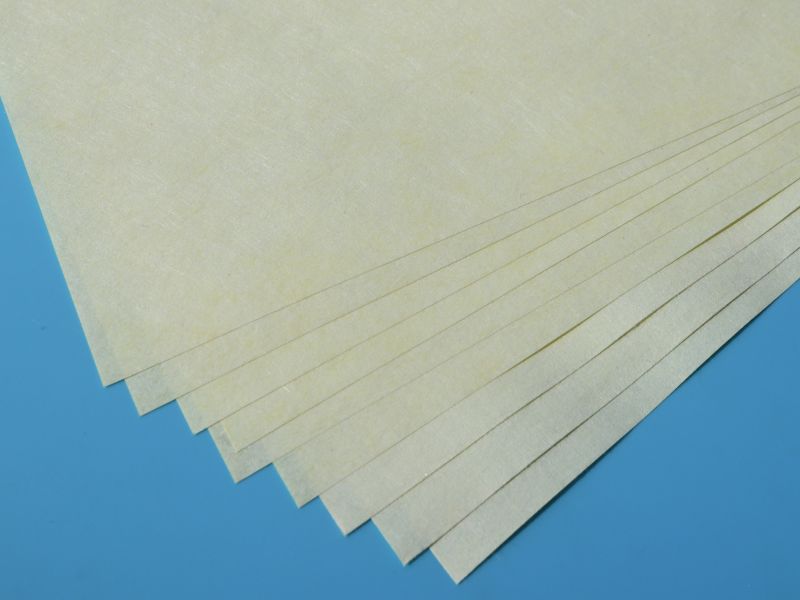

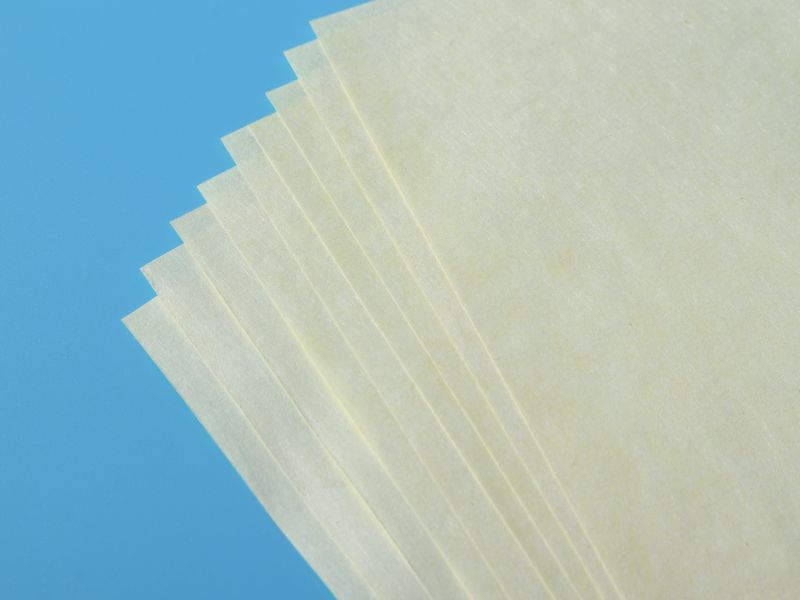

Nomex Paper

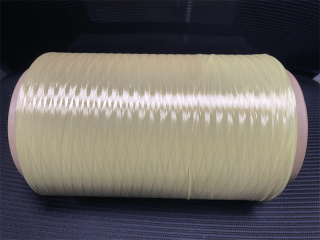

Nomex Paper is a highly resilient, synthetic material renowned for its exceptional thermal and electrical insulation properties. Its ability to withstand extreme heat makes it ideal for use in demanding environments such as electrical insulation, aerospace, and automotive applications. The paper is also flame-resistant, offering added safety in high-risk conditions. Nomex Paper maintains its performance even when exposed to harsh chemicals and mechanical stress. Its lightweight yet durable nature ensures reliability across a wide range of industries, making it a preferred choice for engineers seeking effective insulation and protection solutions in both industrial and commercial applications.

1. Overview of Nomex Paper

Nomex Paper is a high-performance synthetic material known for its exceptional durability and heat resistance. Widely used in various industries, it offers unmatched electrical insulation and thermal protection. This lightweight material is designed to withstand harsh environments, making it a popular choice in applications requiring high safety standards. With its ability to maintain integrity under extreme conditions, Nomex Paper has become a preferred solution for electrical insulation and thermal management.

2. Applications of Nomex Paper

· Electrical Insulation: Nomex Paper is commonly used in the manufacturing of transformers, motors, and generators due to its excellent insulating properties.

· Aerospace Industry: It plays a critical role in protecting aircraft components from heat, making it essential in the aerospace sector.

· Automotive Applications: Nomex Paper is used in electric vehicles (EVs) for its capacity to resist high temperatures and prevent electrical failures.

· Fire-Resistant Gear: Its heat-resistant characteristics make it an essential material in protective clothing, such as firefighter uniforms and other heat-protective equipment.

· Electronics: It serves as a reliable insulator in various electronic devices, ensuring longevity and safety in high-performance gadgets.

3. Key Features of Nomex Paper

· High Heat Resistance: Nomex Paper can endure temperatures up to 220°C without losing structural integrity.

· Lightweight Yet Durable: Despite its lightweight nature, it provides robust protection and strength in demanding environments.

· Chemical Stability: It resists most chemicals, oils, and solvents, ensuring longevity even in corrosive conditions.

· Electrical Insulation: Nomex Paper’s excellent dielectric properties make it ideal for use in electrical systems.

· Flame Retardancy: The material is inherently flame-resistant, adding a layer of safety in high-risk applications.

· Flexibility: Its versatility allows it to be easily shaped and applied in different industrial settings without compromising its structural benefits.

Nomex Paper is a trusted material that combines safety, reliability, and performance, making it indispensable across multiple industries.

Nominal Thickness | mil | 2 | 3 | 5 | 7 | 10 | 12 | 15 | 20 | 30 | Testing standard |

mm | 0.05 | 0.08 | 0.13 | 0.18 | 0.25 | 0.3 | 0.38 | 0.51 | 0.76 | ||

Typical Thickness | mm | 0.052 | 0.078 | 0.13 | 0.18 | 0.255 | 0.29 | 0.38 | 0.515 | 0.765 | GB/T451.3-2002 |

Basis Weight | g/m2 | 41.5 | 63 | 116 | 170 | 252 | 291 | 376 | 510 | 710 | GB/T451.2-2002 |

Density | g/cc | 0.79 | 0.8 | 0.9 | 0.94 | 0.99 | 1 | 0.99 | 1 | 0.93 |

|

Tensile Strength N/cm | MD | 41 | 66 | 130 | 200 | 290 | 340 | 420 | 500 | 650 | GB/T12914-2008 |

CD | 17 | 29 | 60 | 75 | 120 | 155 | 250 | 345 | 450 | ||

Elongation% | MD | 7.5 | 9.5 | 10.5 | 11.5 | 11.5 | 10.5 | 12 | 13 | 13 | |

CD | 7 | 9.5 | 11.5 | 12.5 | 13.5 | 10.5 | 13 | 13 | 12 | ||

Tear Strength N | MD | 0.65 | 1.05 | 2.2 | 3.5 | 5 | 6.5 | 10 | 13 | N/A | GB/T455-2002 |

CD | 1.1 | 2.05 | 3.8 | 4.8 | 6 | 8 | 13.5 | 16 | N/A | ||

Shrinkage at 300℃ % | MD | 3.5 | 3.5 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | IEC60819-2:2002 |

CD | 3 | 3 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2 | 2 |