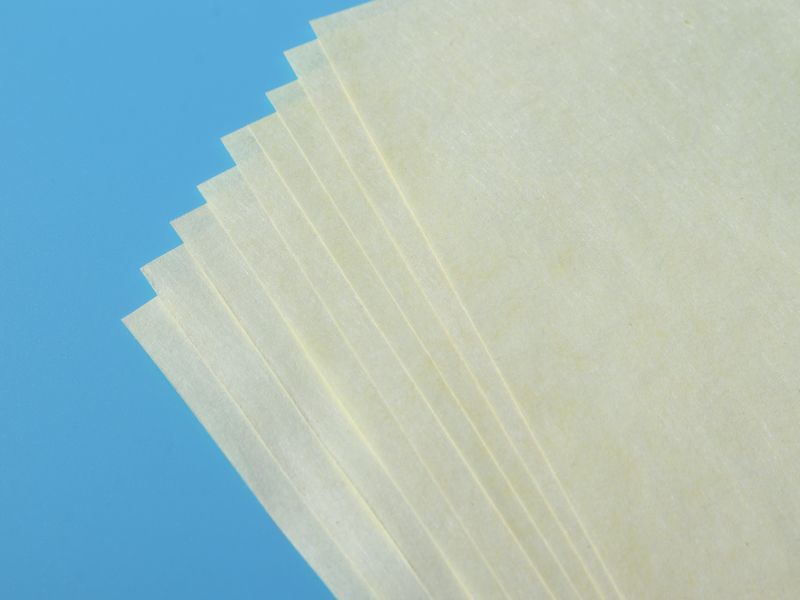

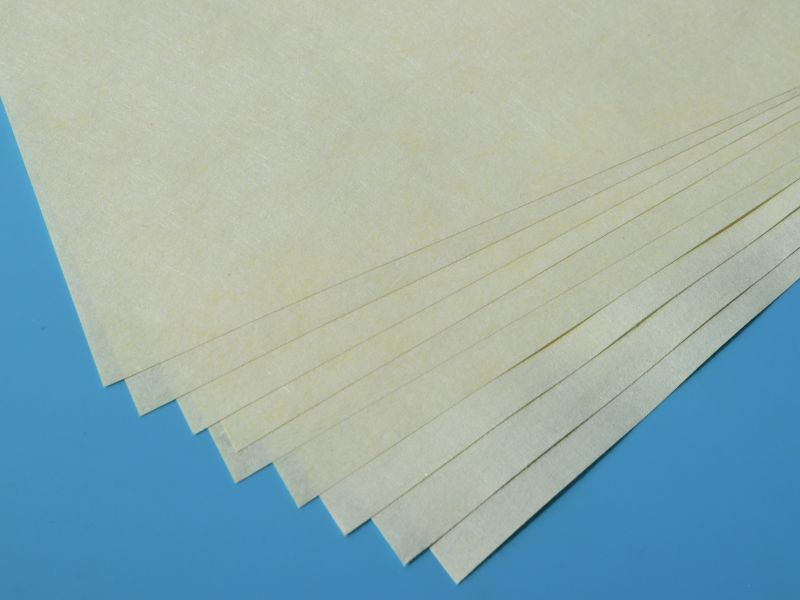

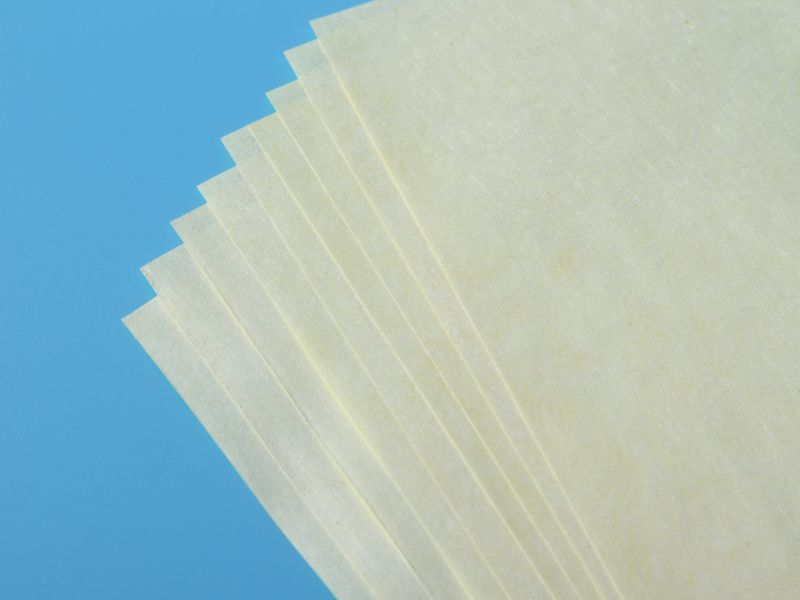

Wet-laid Aramid Paper

Wet-laid Aramid Paper is a high-performance material recognized for its exceptional strength and thermal resistance. Crafted through a specialized wet-laying process, it features evenly distributed aramid fibers, resulting in enhanced durability and flexibility. This innovative paper is lightweight yet robust, making it suitable for a variety of demanding applications across aerospace, automotive, electronics, and construction industries. Its ability to withstand extreme temperatures and harsh chemicals adds to its versatility. Additionally, Wet-laid Aramid Paper can be customized in thickness and density, meeting specific industry requirements while ensuring reliable performance in critical environments.

WET-LAID ARAMID PAPER

1. Product Introduction

Wet-laid Aramid Paper is an advanced material renowned for its high strength and thermal stability. This unique product is manufactured using a wet-laid process, which enhances its structural integrity and uniformity. With its exceptional properties, Wet-laid Aramid Paper is increasingly being adopted in various industries for its reliability and performance.

2. Product Applications

· Aerospace: Utilized in components requiring high durability and heat resistance.

· Automotive: Ideal for brake linings and other high-temperature applications.

· Electronics: Used in insulation and protective layers due to its dielectric properties.

· Construction: Serves as reinforcement in composites for enhanced strength.

3. Product Features

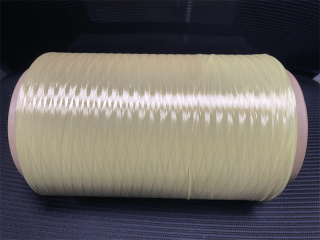

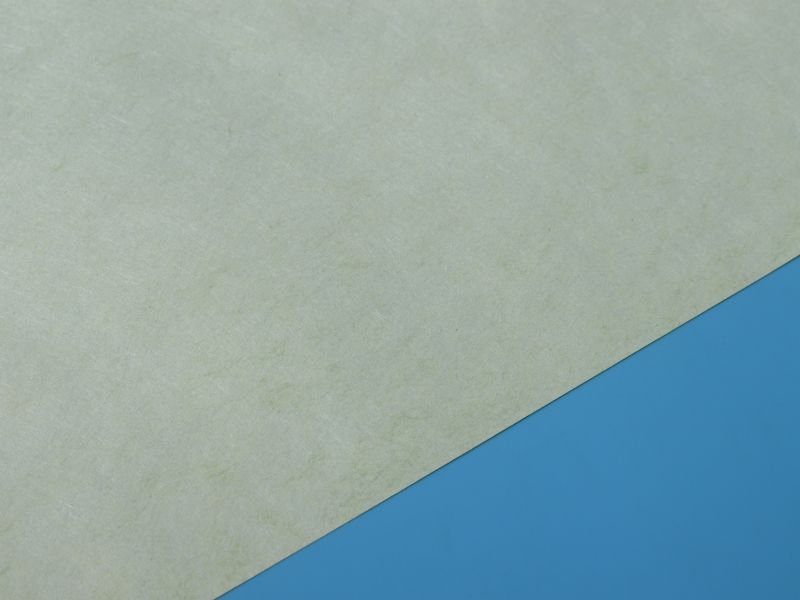

Wet-laid Aramid Paper stands out due to its unique production method, which involves dispersing aramid fibers in water before forming them into sheets. This process not only ensures a consistent fiber distribution but also improves the paper's tensile strength and flexibility. The result is a highly durable material that withstands extreme temperatures and harsh environments, making it suitable for critical applications. Other features include:

· Lightweight: Easy to handle and transport.

· Chemical Resistance: Withstands exposure to various chemicals without degradation.

· Customizability: Available in various thicknesses and densities to meet specific needs.

Nominal Thickness | mil | 2 | 3 | 5 | 7 | 10 | 12 | 15 | 20 | 30 | Testing standard |

mm | 0.05 | 0.08 | 0.13 | 0.18 | 0.25 | 0.3 | 0.38 | 0.51 | 0.76 | ||

Typical Thickness | mm | 0.052 | 0.078 | 0.13 | 0.18 | 0.255 | 0.29 | 0.38 | 0.515 | 0.765 | GB/T451.3-2002 |

Basis Weight | g/m2 | 41.5 | 63 | 116 | 170 | 252 | 291 | 376 | 510 | 710 | GB/T451.2-2002 |

Density | g/cc | 0.79 | 0.8 | 0.9 | 0.94 | 0.99 | 1 | 0.99 | 1 | 0.93 |

|

Tensile Strength N/cm | MD | 41 | 66 | 130 | 200 | 290 | 340 | 420 | 500 | 650 | GB/T12914-2008 |

CD | 17 | 29 | 60 | 75 | 120 | 155 | 250 | 345 | 450 | ||

Elongation% | MD | 7.5 | 9.5 | 10.5 | 11.5 | 11.5 | 10.5 | 12 | 13 | 13 | |

CD | 7 | 9.5 | 11.5 | 12.5 | 13.5 | 10.5 | 13 | 13 | 12 | ||

Tear Strength N | MD | 0.65 | 1.05 | 2.2 | 3.5 | 5 | 6.5 | 10 | 13 | N/A | GB/T455-2002 |

CD | 1.1 | 2.05 | 3.8 | 4.8 | 6 | 8 | 13.5 | 16 | N/A | ||

Shrinkage at 300℃ % | MD | 3.5 | 3.5 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | IEC60819-2:2002 |

CD | 3 | 3 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2 | 2 |

ed.sales10