Enhancing Pipe Heating Efficiency with Carbon Fiber Mat/Veil for the Composite Pipeline Industry

2024-10-28 11:22

In industries involving the transportation of water, natural gas, oil, and other fluids, maintaining consistent pipeline temperatures is critical for efficiency and safety. Carbon Fiber Mat/Veil have emerged as an ideal solution for pipe heating applications, especially in composite pipelines where reliability, high performance, and energy efficiency are paramount.

Why Carbon Fiber Mat/Veil for Pipeline Heating?

Carbon Fiber Mat/Veil offer a unique combination of conductivity, low resistance, and compatibility with various resin systems, including epoxy, vinyl ester (VE), and polyethylene (PE). These features enable them to function effectively as heating elements when integrated into composite pipelines. Unlike conventional heating systems that consume significant power, Carbon Fiber Mat/Veil are designed to produce heat efficiently, reducing overall power consumption.

Key Features and Benefits:

1. Excellent Conductivity and Low Resistance:

The Carbon Fiber Mat/Veil’s low resistance enables it to reach high temperatures quickly with minimal energy consumption. In tests, a 47gsm carbon fiber veil demonstrated the ability to heat from room temperature to 167°C in just 15 seconds under 28V and 6A power at 6Ω. This rapid heating performance allows for efficient temperature control without excessive energy demands, meeting the customer’s requirement for a low-power, high-heat system.

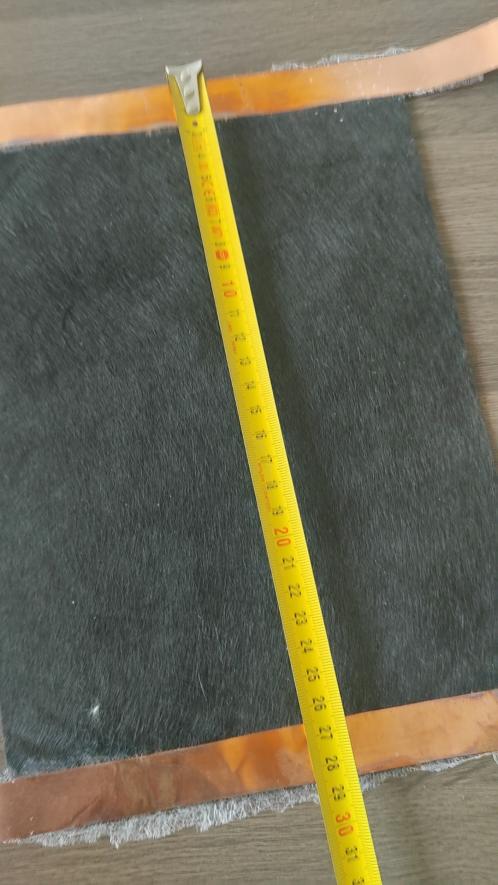

Sample before Test:

47gsm Carbon Fiber Mat/Veil

Testing Machine:

Test at 28V, 6A, 6Ω

Test Result:

2. Compatibility with Multiple Resin Systems:

These Carbon Fiber Mat/Veil integrate seamlessly with epoxy, VE, and PE resins commonly used in composite pipelines. This compatibility allows for versatile application across various pipeline materials without compromising the bonding strength or structural integrity of the composite material.

3. Durability and High Temperature Stability:

Carbon Fiber Mat/Veil are inherently robust and designed to endure high temperatures and harsh conditions without deteriorating. This stability ensures that the heating element remains effective throughout the pipeline’s operational lifespan, even under demanding environmental conditions.

4. Cost Efficiency and Energy Savings:

Due to their low resistance and high conductivity, Carbon Fiber Mat/Veil require less power to generate sufficient heat, reducing operational costs and making them a cost-effective heating solution for pipeline systems.

Conclusion:

For composite pipeline manufacturers looking to enhance the efficiency and durability of their heating systems, Carbon Fiber Mat/Veil offer a high-performance, energy-efficient solution. With quick heating capabilities, compatibility with key resin types, and reliable performance, they are a forward-thinking choice in pipeline heating technology. This innovation not only meets industry demands for temperature control but also offers a sustainable option that reduces energy consumption.