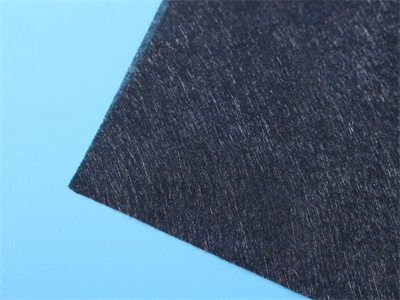

Carbon Fiber Paper used for GDL Substrate

Carbon Fiber Paper for GDL Substrate is a high-performance material designed specifically for use in fuel cell applications.

1. Product Overview

● Carbon Fiber Paper for GDL Substrate is a high-performance material designed specifically for use in fuel cell applications.

● This innovative product combines the unique properties of carbon fiber with the versatility of paper, offering an ideal solution for gas diffusion layers (GDLs).

● The carbon fiber structure enhances strength, conductivity, and durability, making it a critical component for fuel cell technology.

● Whether used in automotive, energy, or industrial sectors, this paper-based material ensures superior performance and reliability in demanding environments.

2. Applications

Carbon Fiber Paper for GDL Substrate is widely used in various industries, particularly in fuel cell production and energy storage technologies. Some of its primary applications include:

● Fuel Cell Technology: Utilized as a gas diffusion layer in proton exchange membrane (PEM) fuel cells, optimizing the transport of gases and enhancing overall fuel cell efficiency.

● Energy Storage: Employed in battery technologies where high conductivity and durability are essential for optimal energy conversion and storage.

● Automotive Industry: Helps improve fuel efficiency and reduce emissions in hydrogen-powered vehicles.

● Industrial Manufacturing: Used in advanced energy solutions, providing a lightweight, conductive material for complex applications requiring high thermal stability.

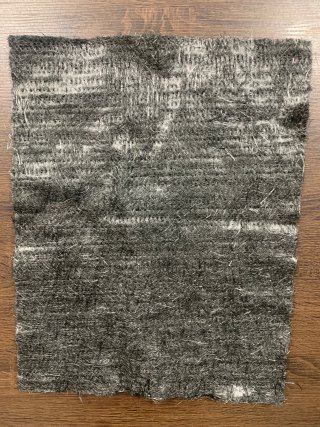

3. Product Features

● Lightweight and Durable: Carbon Fiber Paper for GDL Substrate is incredibly lightweight, making it ideal for applications where weight reduction is essential, without compromising on strength.

● Excellent Conductivity: Its carbon fiber structure ensures superior electrical and thermal conductivity, critical for optimizing performance in fuel cell systems and other energy applications.

● High Thermal Stability: The material is highly resistant to high temperatures, making it suitable for use in demanding environments where temperature fluctuations are a concern.

● Chemical Resistance: It is resistant to various chemicals, ensuring long-term durability in harsh conditions.

● Flexibility: The paper-like material is easy to handle and shape, making it suitable for a variety of industrial processes.

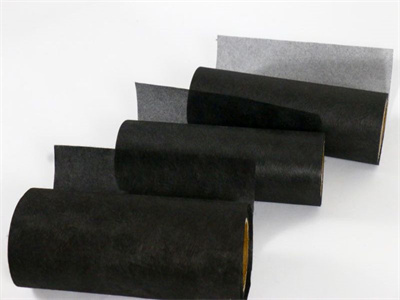

● Customization: Available in different thicknesses and densities, allowing for tailored solutions based on specific customer needs.

Area Weight | Thickness | Tensile Strength | Moisture Content |

g/m² | mm | N/50mm | % |

6±1 | 0.06±0.01 | 2.5±0.5 | ≤0.28 |

8±1 | 0.08±0.01 | 5.5±0.5 | ≤0.29 |

10±1 | 0.09±0.01 | 5.6±0.5 | ≤0.295 |

15±1 | 0.13±0.01 | 6.9±1 | ≤0.35 |

20±1 | 0.18±0.02 | 11±2 | ≤0.37 |

30±2 | 0.21±0.02 | 16.9±2 | ≤0.38 |

50±2 | 0.38±0.02 | 25.8±0.3 | ≤0.38 |