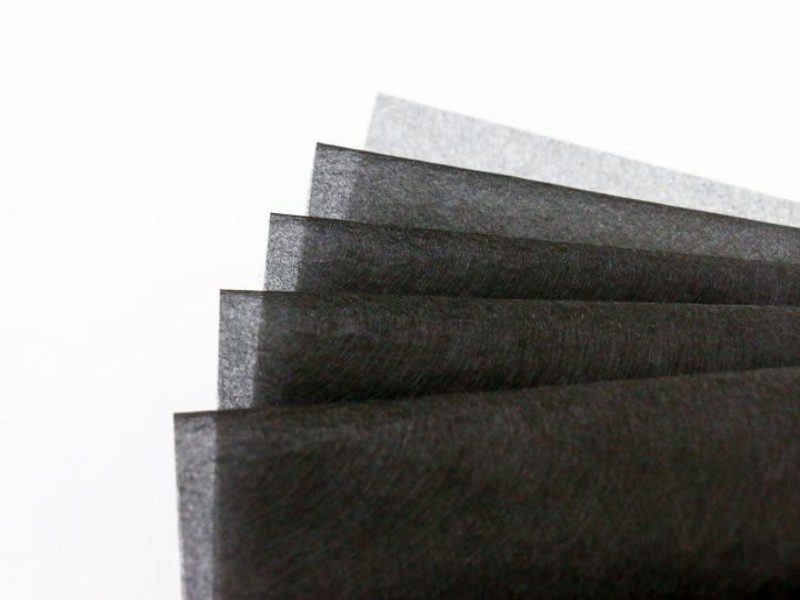

Uniform distribution wet-laid process carbon fiber veil

Our wet-laid process carbon fiber veil, renowned for its uniform distribution and robust adhesive carrier, stands out in the market. Leveraging advanced R&D techniques and strong production capabilities, this product has been successfully integrated into aerospace and automotive industries, demonstrating remarkable sales and consistent inventory levels. With its versatility and superior quality, it is a testament to our commitment to innovation and excellence in advanced materials.

1. Product Introduction

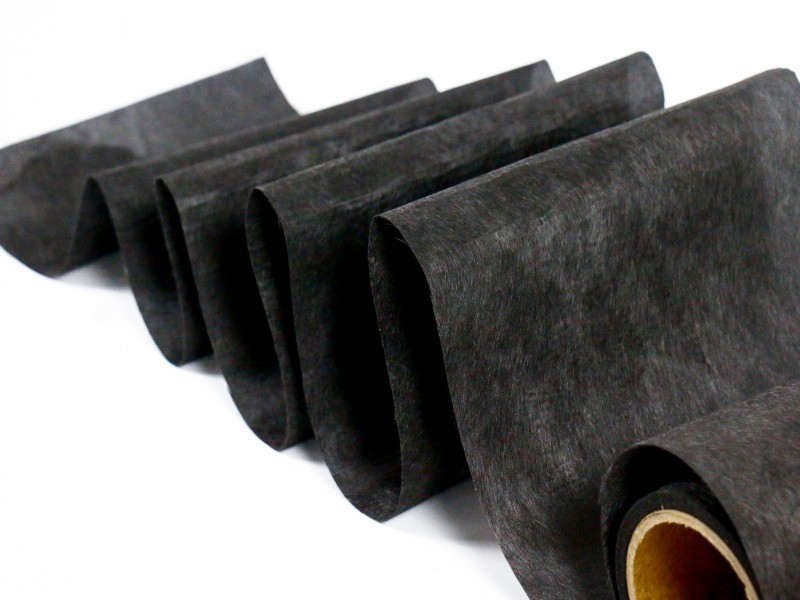

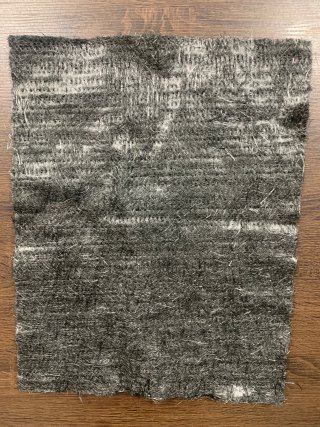

Our carbon fiber wet-laid process veil is a versatile, lightweight non-woven fabric. Utilizing an innovative wet-laid process, this material arranges fixed-length chopped PAN-based carbon fibers in a random yet uniform manner, creating a multi-layered microporous network structure.

During the fabrication process, after the fibers are layered, an adhesive carrier is applied to secure the fibers. This step provides the necessary mechanical strength and surface toughness to the veil. By fine-tuning the adhesive formula and its concentration, we enhance both the bonding characteristics and the resin compatibility of our wet-laid process carbon fiber veil.

This product is distinguished by its exceptionally low grammage, customizable to as little as 4g/m². The result is an ultra-light and ultra-thin veil with an outstanding dispersion effect. In terms of mechanical properties, the strength of our high-strength carbon fiber wet-laid process veil significantly surpasses that of wood. Its specific strength and modulus are 4 times and 3 times greater than that of fir, and 3.4 times and 4.4 times that of sycamore, respectively.

The uniform distribution of the carbon fiber veil achieved through our wet-laid process, along with the use of a high-quality adhesive carrier, makes our product an ideal choice for a variety of applications requiring lightweight yet strong materials.

2. Product Feature

Uniform Fiber Distribution: Achieved through a meticulous wet-laid process, ensuring consistent quality and performance.

Adhesive Carrier Integration: Expertly incorporates an adhesive carrier for easy application and superior bonding.

High Durability: Designed to withstand demanding conditions, providing long-lasting performance.

Versatile Applications: Ideal for use in automotive, aerospace, and industrial applications where strength and light weight are crucial.

3. Product Details

1

Material Composition

High-quality carbon fibers, uniformly distributed for optimal strength.

2

Manufacturing Process

Utilizes advanced wet-laid technology to ensure uniform distribution of fibers.

3

Product Specifications

Available in various dimensions to suit diverse application needs.

4

Quality

Assurance

Rigorously tested for durability and performance under various conditions.